Around the world, cleaning of wastewater is in most cases done via the activated sludge process. The basic concept is to mix incoming wastewater with a refined bacterial suspension optimized for the biological properties in the activated sludge plant. This bacterial suspension is called “activated sludge”.

The physical properties of the activated sludge determine many of the most energy demanding processes and the efficiency of wastewater treatment plants. A typical example of this is the settling properties of the sludge, which determines how easy it is to separate the sludge from the cleaned water. But also, the dewatering properties and compressibility of the sludge are important parameters for the costs of disposing the sludge.

Due to the many important derived effects of sludge physical properties, for many years there has been a strong focus in the scientific community develop methods to test these properties and figure out which properties are important. However, the implementation of these new methods in routine plant management is still lacking. We believe that an important explanation for this is that the methods/equipment still needs to be developed into something that is applicable for routine lab application, instead of the scientific protocols and prototypes that exist now.

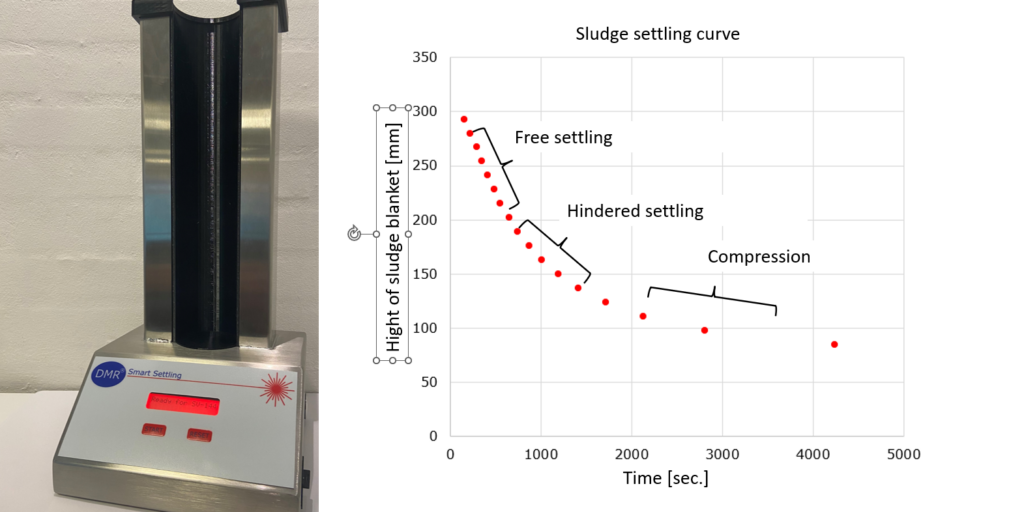

As a first step in the implementation of more sludge physics measurements, we have developed a new lab device (DMR Smart Settling) for measurement of sludge settling (see picture). This device takes the step from simple DSVI measurements, to actual measurements of sludge settling speed in different phases.

We are currently working on a new hardware and software package that can analyze more sludge physical properties. Our goal is to automize and simplify as many of the developed methods as possible which in the end will make it realistic for them to be implemented as routine measurements and wastewater treatment plants.