This ECOFluX gas flux chamber sets a new standard for measuring CO2 dynamics at the ecosystem level. As the chamber can be transparent as well as darkened, both Net Ecosystem Exchange (NEE) and Ecosystem Respiration (ER) can be measured directly and Gross Ecosystem Photosynthesis (GEP) can be estimated by their difference (GEP = NEE – ER), thus producing direct data of the processes behind NEE. The chamber covers a ground area of 3,100 cm2 and has a volume of 220 L (at a standard height of 80 cm) and is therefore big enough to include plants communities in many natural low-stature ecosystem types as well as many agricultural crops. This double chamber (dark and light permeable) feature basically yealds two chambers in one and ensures that measurements with and without light are done in the exact same plot.

Another great advantage of the automated chamber is that the chamber rises from the bottom (see video below). This ensures minimal harm to plants/crops inside the chamber, and thereby minimal disturbance of the natural system. Furthermore we have focused on the lowest possible hight of the chamber in ”rest” situations, to minimize establishment of micro climates inside the chamber that differs from natural system.

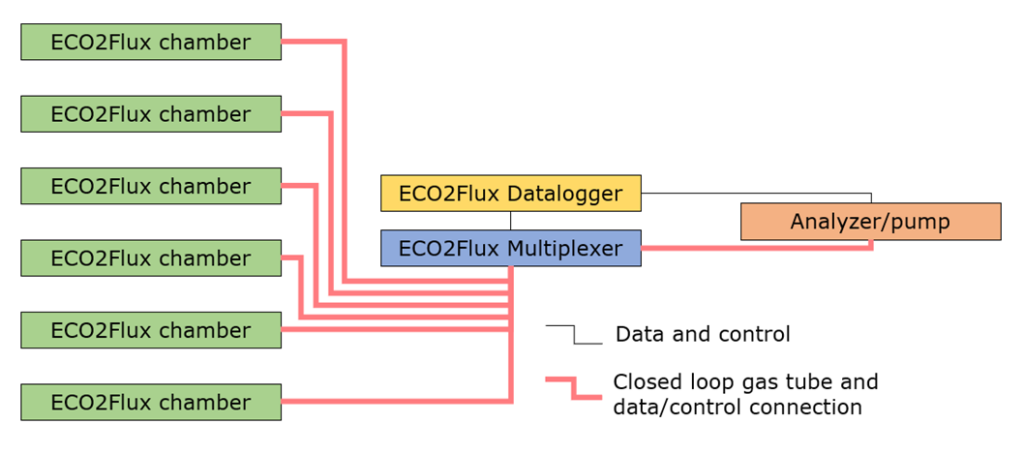

An overview/schematic of a typical system is shown in the figure to the right. In this system we have configured 6 ECOFlux chambers (link til shop), and they are individually controlled via the datalogger (link til shop). It is possible to configure all parameters like the individual open and closing time for the chambers, flushing before and after and the order in which the chambers are activated.

Typically a cycle (both light and dark) for a chamber takes 20-30 minutes depending on the flux, which means that a flux measurement for all 6 chambers will take 2-3 hours or 8-12 flux measurements from each chamber in 24 hours.

We have supplied similar automatic systems for quantification of ammonia emission as well. Is this case it is important to address that ammonium is well known for its sticky properties throughout emission studies. It is possible for us to bypass this as all non teflon parts can be delivered in a teflon coated version.

A typical setup for application of automatic chambers includes:

- Automized ECOFlux chamber.

- Datalogger combining all data from analyzer and auxiliary sensors and controlling the chambers.

- Multiplexer in a 6 or 12 channel version (Link til shop).

- Analyzer with pump (e.g. the ECOFlux CO2 analyze or from other analyzer suppliers).

- Optional auxiliary sensors like PAR, Chamber temperature or soil humidity/temperature.

We can also supply an innovative new version of our Autochamber modified for wetlands, ditches and shallow streams. This is presented in the video below. This chamber works like the normal ECOFluX chamber, with connectivity to via multiplexer, datalogger, and possibilities for connecting sensors.

When measuring ammonia emission, it is also worth considering the bulk analyzer based on PID sensor technology. It is a very sensitive sensor, and as ammonia e.g., in crop systems often (by far) is the component with the highest concentration, the bias from other VOC’s measured with the PID-sensor is neglectable. If this is relevant for your project, applying the bulk analyzer can give you large savings compared to more sophisticated and gas specific analyzers for ammonia. Our experts are ready to help you to get the best setup for your project.