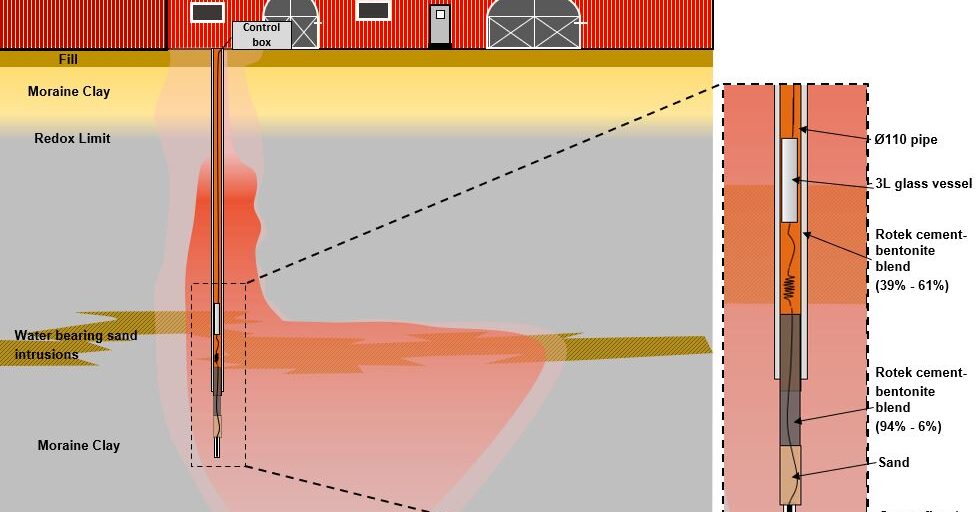

The installation and equipment for automated soil water sampling is developed and optimized for deep installations (>5 m b.g.l.). The biggest challenge we have circumvented when performing deep installations is that we apply vacuum for extraction of the pore water, but also for elevating the water to the sampling at ground level. As it is only possible to lift water 10 m with vacuum and we also need vacuum capacity for water extraction, this is a limitation without a special installation technique which is illustrated in the figure above. As shown in the figure, we install a 110 mm pipe down to roughly 1 m above the installation depth. Then we lower the sampling bottle through the pipe, down to approximately 2 m above the installation depth. This means that we have plenty of vacuum left for soil water extraction. Using this technique, we have no limitations on how deep we can install.

The installation technique also ensures that it is possible to install soil water samplers in unsaturated layers below secondary aquifers. This is also illustrated in the figure above, where we install the sampler in moraine clays below water bearing sand intrusions. When we install the 110 mm pipe, we make the drilling (6”) as a cased borehole. Then we install the 110 mm pipe and make a water impermeable plug between the casing and the pipe using a suspension of cement and bentonite (39 % – 61 %). After this the casing can be pulled up, and the last m to the installation depth is drilled using a 4” drill. From our experience, a cement plug of at least 1,5 m between the water bearing layer and the bottom of the 110 m pipe is necessary to ensure a tight plug. The complete installation procedure can be found here.

Each sampling point consist of:

- A porous water sampler (e.g. PRENART SUPER STEEL).

- Twisted tube (e.g. Twisted FEP).

- Silica flour to ensure hydraulic connection between sampler and unsaturated zone.

- Special sampling bottle (e.g. glass).

- Customized bottle cap (e.g. Srew cap (POM)).

As shown in the figure above, we also add sand, (e.g., standard filter sand for installation of groundwater wells) and bentonite/cement powder just above the installed soil water sampler. The purpose of the bentonite is to avoid surface water to reach the sampler through the 110 mm pipe and the sand is used to avoid bentonite from blocking the fine pores in the sampler. After installation, the vacuum can be established using e.g., the portable vacuum pump. In the figure above, we have installed an optional control box. The benefit of using this box is that it continuously keeps the vacuum on the desired level, and it also measures how much water is sampled. This data is sent to our DMR cloud which means that it is possible to follow how much water is sampled and other data like the battery level. This is particularly beneficial if the site is far from the office.

The procedure described above is primarily applicable for nonvolatile compounds (like most pesticides, PFAS and long chain oil constituents), because of the risk, that the applied vacuum will strip the sample from the substance of interest. If it is desired to test for volatile compounds (like most chlorinated compounds from cleaning facilities), it is possible to install a sorbicell (small tube with adsorbent) before the water enters the sampling bottle. If this is the case, the water flow through the sorbicell must be lover than 250 ml/day. This can be controlled using the optional control box, by running it in flow control mode. Please contact our experts below if you are interested in this option.

The equipment we supply is prepared and tested for vacuum purposes, to ensure that the bottle does not collapse, and the risk of leaks are minimized. For each specific project, it is however important to evaluate which specific tubes that are most suitable. Especially regarding choice of sampler, tube and bottle that is most relevant for each specific chemical. Our specialists listed below can help you selecting the best options for your project. We can also help install the probes and all stages of data interpretation, risk assessment etc.